This post is taken from an original paper presented at Brian Cherry International Concrete Symposium 2017.

Author:Barry Wright

New Zealand Transport Authority

A summary of New Zealand Transport Agency (NZTA) experiences with corrosion of concrete road bridges on the NZ state highway network. In summary it covers research findings together with specific examples of corrosion and current interpretations of durability performance. It also outlines management approaches that have been used in the past or are currently being developed and implemented

INTRODUCTION

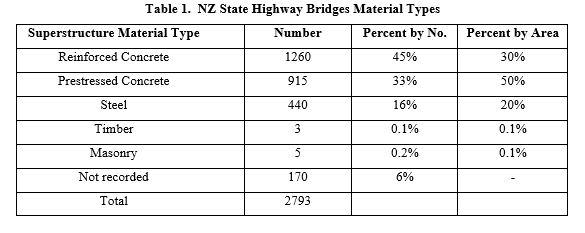

The NZ state highway network includes approximately 4,300 bridges and major culverts. The structures numbers and material types are summarised in Tables 1 and 2 below. A summary valuation is shown in Table 3.

The average bridge age on the state highway network is approximately 40 years old compared to the standard design life of 100 years. The bridge asset is therefore relatively young. However, approximately 5% of existing structures are over 90 years old and approximately 17% are over 80 years old.

In addition to this there are approximately 13% of all NZ state highway bridges located in the coastal frontage or tidal splash/spray environments and are therefore more susceptible to chloride ingress causing steel reinforcement (conventional and prestressing) corrosion.

2. BRIDGE MANAGEMENT PRACTICES

The inspection and maintenance management of state highway structures is outsourced to consultants through ten contracts that cover the whole country. Bridge inspections are specified to identify defects and there are processes in place to cover the development of maintenance proposals, funding, design and physical works. This has generally resulted in a reactive approach to corrosion in reinforced and prestressed concrete bridges. When defects, such as concrete spalling, were identified then wider investigations would be instigated to determine the scope, severity and urgency of the issue.

Historically there was no formal national policy for proactive investigations of corrosion but such work could have been promoted by the New Zealand Transport Agency (NZTA) and/or the regional bridge inspection engineer.

A research project to investigate the condition of bridges deemed to be at higher risk of corrosion was completed in 2013, as outlined in Section 3 below.

NZTA has also recently developed a screening process to identify bridges with the potential for failure under live load. This includes bridges at a high risk of corrosion. The screening process has been implemented through the regions but the results have not yet been completed and considered. It is anticipated that the results will provide a prioritised schedule of structures that will then require more detailed investigations of individual bridges.

3. RESEARCH PROJECT

3.1 Project outline

An NZTA research project was carried out entitled “Assessing Pre-tensioned Reinforcement Corrosion within the New Zealand Concrete Bridge Stock” (Rogers et al, 2013). The primary aim of the project was to obtain an accurate assessment of the severity, prevalence and distribution of corrosion damage to all of New Zealand’s pre-tensioned prestressed concrete bridges.

The project was initiated because a large number of pre-tensioned concrete bridges had been constructed between 1950 and the 1970s and it was recognised that many of these designs did not meet current durability criteria and also included design characteristics which predispose them to corrosion of the pre-tensioned reinforcement. In addition it is recognised that corrosion of pre-tensioned concrete is more critical than corrosion of conventional steel reinforced concrete.

The project identified 137 bridges as having a high likelihood of being at risk of pre-tensioned reinforcement corrosion either now or in the future. These bridges were identified as being actually in a saline environment or being within 1km of the coast. A sample of 30 of these bridges was then selected for more detailed inspection and investigation.

In summary, 29 of the 30 inspected bridges were found to be affected by chloride ingress with 8 of these predicted to experience reinforcement corrosion within a 100 year service life as a result of that chloride ingress. In 4 of these cases the corrosion was of the shear reinforcement and in the other 4 it was corrosion of the pre tension reinforcement.

The research project also found cast-in chlorides in the prestressed bridges due to the use of chloride-based set accelerating admixtures. More specifically, of the 30 coastal bridges they investigated, 29 were affected by chloride ion contamination and 21 included cast-in chlorides.

3.2 Project Examples of Affected Bridges

The Tiwai Bridge is located near Bluff in Southland and crosses Awarua Bay. It was constructed in 1969 and comprises 27 spans of T beams. The bridge is located in a coastal saline environment and inspection in 2004 identified serious corrosion of the pre tensioned strands, refer photo at Section 9.1. The cause of the early failure was attributed to very low concrete cover and also the fact that the shear reinforcement did not enclose the strands. The super-structure was replaced in 2010.

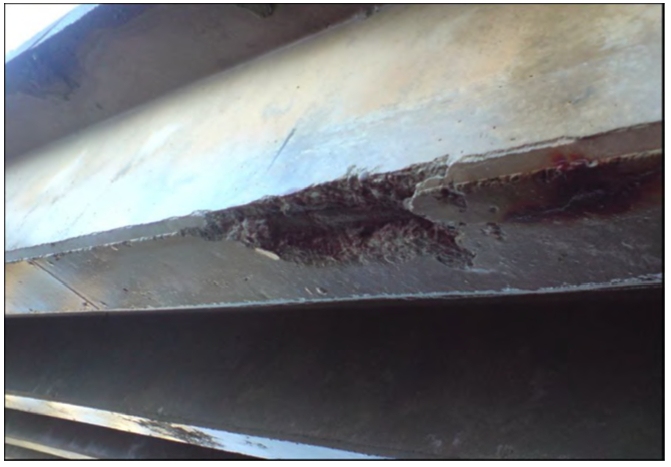

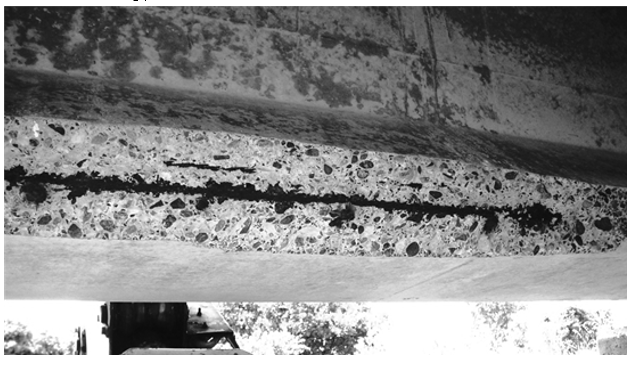

The Boundary Bridge was constructed in 1963 and comprises a single span of precast, pre tensioned concrete I beams. The bridge is located north of Thames at the base of the Coromandel Peninsular in the North Island and specifically in the coastal exposure zone. Visual inspection had already identified severe corrosion of the pre tension reinforcement within the I-beams, refer photo at Section 9.2, with the entire cross section of several wires in the bottom layer of pre-tensioned reinforcement being lost. This was attributed to low cover and the fact that the shear reinforcement did not enclose the pre-tension reinforcement. Extensive remediation works were completed in 2010.

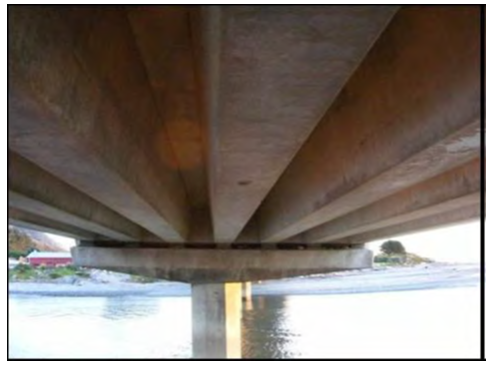

The Fox River Bridge is located south of Westport in the West Coast region of the South Island. It was constructed in 1969 comprising multiple spans of I beams located in the coastal zone, refer photo at Section 9.3. Inspection indicated that the bridge was generally in good condition with no visible signs of any significant defects. Chloride ingress measurements and modelling indicated that the initiation of corrosion of the stirrups would occur after about 43 years and pre tension reinforcement about 12 years later. Subsequent more detailed investigations demonstrated that corrosion had not actually initiated and that it was probable that the structure could be managed to achieve the 100 year design life. The structure continues to be monitored (Lee, 2017).

The Ngakawau Bridge was constructed in 1992 and comprises 5 spans of U beams, refer photo at Section 9.4. The bridge is located north of Westport in the West Coast region of the South Island, also in a coastal saline environment. Inspection indicated that the bridge was in excellent condition with no apparent signs of corrosion of reinforcement or strand. Initial investigations and modelling showed that there were no cast-in chlorides but that chloride ingress could result in corrosion initiation levels at the pre tension reinforcement after just 18 years. Subsequent more detailed investigations demonstrated that corrosion had not actually initiated and the structure continues to be monitored (Lee, 2017).

The Hamanatua Bridge was constructed in 1966 and comprised 3 spans of I beams. It is located near Gisborne on the east coast of the North Island. The bridge is 200m from a surf beach and is nominally in the B2 exposure zone but at the more aggressive end of that zone. Concrete cover to the prestressing steel was specified at 25mm, well below the current code requirements. In addition the transverse reinforcement does not fully enclose the pretensioned strands.

Routine inspection of the Hamanatua Bridge identified splitting cracks in the lower flanges of some of the I-beams and subsequent investigation revealed the cracking was as a result of corrosion of the prestressing steel, refer photo at Section 9.10. The cause of the corrosion was atmospheric chloride ion contamination. Structural analysis was carried out to assess the impact of the prestressing strand corrosion which showed the bridge capacity was not significantly affected due to the short lengths of corrosion and the fact that the worst affected beam was under the footpath. It was subsequently decided to repair the beams using a proprietary cement-based patch repair system incorporating galvanic zinc anodes to guard against incipient anode formation.

3.3 Research Conclusions

In summary the key conclusions of the research project were:

- Corrosion occurs primarily in the coastal exposure zone but can also occur in adjacent zones,

- Cast-in chlorides due to the use of chloride-based set accelerating admixtures were identified in 21 out of the 29 bridges in the coastal zone affected by chloride contamination. Cast-in chlorides occurred in some beams but not in others on the same bridge.

- Chloride build up on the surface of a structure varies significantly even in apparently the same conditions of location and exposure.

- The critical location for chloride ingress (i.e. the location with the highest level of chloride ingress), varies significantly even in apparently the same conditions of location and exposure. The critical location for chloride on any bridge cannot therefore be predicted.

- Similar designs in similar exposure zones performed quite differently.

- Some bridges have poor chloride resistance for unknown reasons.

- Some bridges had low surface chloride concentrations in the Coastal exposure zone for no apparent reason.

4. CORROSION OF REINFORCED CONCRETE BRIDGES

4.1 Introduction

Almost half of the bridges on NZ state highways are constructed from conventional steel reinforced concrete and these are generally also the older bridges on the network.

There are hundreds of conventionally reinforced concrete T beams that were constructed to standard designs of the time (1930s’), across the full range of exposure zones. The standard specification for concrete cover varied from 1.5 – 2 inches (38-50mm) with concrete strength specifications between 17 and 21MPa. The actual concrete strength often exceeded 30MPa thus enhancing the durability performance. However concrete quality of these bridges was variable with segregation and lack of compaction being a common issue around congested reinforcement at the base of the beams.

A formal systematic review of durability performance has not been undertaken to date. Typical examples of reinforced concrete bridges with corrosion issues are outlined in the next section.

4.2 Examples of Reinforced Concrete Bridges

The old Mangere Bridge is located in the Auckland urban area and was constructed in 1914. It comprises 17 spans of reinforced concrete beams and piers located in the coastal marine environment. The bridge was closed to vehicular traffic in 1985 but remained open for pedestrians and fishermen since then. The bridge has suffered from reinforcement corrosion in the form of extensive cracking, delamination, loss of steel section and concrete spalling as well as ship impact damage, refer photos at Section 9.5. Various maintenance and strengthening works have been carried out since 1985 to maintain the structure with sufficient strength to ensure the safety of pedestrians and other users. These works have included, reinforced concrete jackets to columns, patch repairs, external prestress, partial deck overlay and so on. More recently the access to the deck has been physically restricted in order to limit live load due to pedestrians and fishermen to only those areas of the bridge that can actually support such loads. Other areas are limited to structure dead load only.

The Whirokino Trestle Bridge is located on state highway 1 just north of Levin on the west coast of the North Island. It comprises 90 spans of reinforced concrete beams and piers 6km from the sea in exposure zone B1 but exposed to salt borne prevailing winds. Chloride contamination levels at the depth of the reinforcing steel exceeds 0.1% by weight of concrete which is surprisingly high considering the bridge is 6km from the coast. There is no significant carbonation. The high contamination levels are attributed to the onshore prevailing westerly wind and the lack of any sheltering topography. The concrete spalling on the beams (refer photo at Section 9.8), deck and piers is now extensive and a detailed condition assessment in 2014 showed the bridge had an estimated patch repair volume of about 90 cubic metres. However there has been very little loss of cross sectional area of reinforcement and the structural capacity of the bridge has not yet been directly affected. Repairs have been carried out reactively since about 1985 starting with locally formulated concrete and mortar repairs which later evolved into the use of proprietary cement-based patch repairs. Various patch repairs have been undertaken since then. The maintenance costs over the last 30 years or so have been reasonable despite the patch repairs required and were insufficient to justify replacement of the bridge. The bridge is now being replaced for a combination of durability and functional reasons.

The old Kopu Bridge is located near Thames at the base of the Coromandel Peninsular in the North Island. It comprises 25 spans of steel plate girders with a reinforced concrete deck on reinforced concrete piers in the coastal marine environment. Refer photo at Section 9.9. The bridge was constructed in 1927 and was replaced with a new bridge in 2011 built for functional reasons. The old bridge is a category 1 heritage structure and currently remains intact. The piers are in poor condition with spalling due to corrosion of the reinforcement and some loss of steel section.

High chloride ingress has been recorded in the tidal zone of the structure. Extensive remediation works have not been undertaken to date but will be required if the bridge is to be retained for heritage purposes. It is thought that any form of patch repair would be expensive and futile due to rapid failures and ongoing deterioration. One potential remedial option being considered is some form of partial reconstruction involving jacketing where the piles would be broken out to remove all loose or spalling concrete then jacketed with an 80mm thick jacket reinforced with stainless steel reinforcement. The jackets would be designed to provide the structural support to the bridge with no contribution from the original reinforcing.

4.3 Conclusions

These bridges have generally performed well but in coastal locations some have been replaced already and others are currently being maintained using repeat cycles of patch repairs. The above three examples are typical of the experience across the wider network and support the following conclusions for reinforced concrete bridges:

- Corrosion occurs primarily in the coastal zone but can also occur in adjacent zones under the right circumstances.

- Corrosion results in spalling concrete that usually provides clear signals for inspectors.

- Loss of steel section only occurs slowly often over a period of many years. Therefore remediation works can be delayed and/or managed to extend the life of the bridge for decades at a relatively low cost. This approach usually provides good value for money compared with a bridge replacement.

- The performance of apparently similar bridges in similar circumstances can vary significantly.

5. PATCH REPAIR TECHNIQUES

Conventional patch repair involves the removal of unsound concrete at visibly obvious locations, such as spalls and cracks, to a depth of at least 20 mm behind the reinforcement to eliminate chloride-contaminated concrete. After replacing or treating the steel, as appropriate to the level of corrosion damage, the concrete is reinstated by hand-application, casting or spraying, depending on the volume of the repair. Best practice for conventional patch repairs indicates hydro-demolition for removal of the concrete, use of proprietary Portland cement-based repair materials from reputable manufacturers for reinstatement, and the provision of galvanic zinc anodes to guard against incipient anode corrosion cells developing adjacent to the newly completed repairs.

Well-executed patches are a viable strategy for extending the life of a deteriorating reinforced concrete structure and the repairs should remain durable for at least 10-15 years if protected with galvanic zinc anodes. However where there is more widespread chloride ion contamination it can be expected that other areas of concrete not repaired, may begin to fail within 10 to 15 years and further repairs will be required.

6. PROTECTIVE COATING

A New Zealand Transport Agency research project was carried out into protective coatings to delay corrosion damage of concrete structures (Freitag and Bruce, 2010). The primary findings of the study are summarised below.

- Current design and construction standards should deliver a 100 year service life without surface treatments for concrete.

- In the atmospheric and occasional splash zones, silane and siloxane have the potential to extend the service life of bridges if applied before corrosion damage occurs.

- Surface treatments should not be applied to newly built structures because they might not be able to penetrate the surface sufficiently and may result in concrete drying prematurely reducing potential performance. However they may be used for remedial works by exception, when new concrete does not meet the specified requirements.

- Silicon based penetrants are most cost effective when applied immediately prior to the initiation of corrosion and are most likely to benefit bridges in the most severe exposure classifications B2 and C.

- The justification for protective coatings should be based upon a combination of economic analysis and engineering judgement.

Generally current practice is that surface coatings are only usually applied when other repairs are being carried out and the incremental cost of a coating is small.

7. CATHODIC PROTECTION

The original Causeway Bridge is located on state highway 16 in the Auckland urban area and was constructed in the 1950s using reinforced concrete. The bridge is in a coastal marine environment. The bridge was duplicated in the 1960s using pre-tensioned reinforced concrete I beams and piles. It was then widened in the 1990s using pre-tensioned reinforced concrete U beams and piles. Further widening is now required and so the condition and longevity of the existing structures is a key factor in determining the optimum long term solution.

A durability assessment was undertaken to establish the current condition and to determine probable future durability performance over a period of 50 years. The assessment was conducted on representative samples of the substructure and included the following tests: visual examination; chloride content sampling at varying depths; depth of carbonation; compressive strength of concrete; cement content and type; reinforcement continuity and concrete resistivity.

The test results indicated the following:

- The cover to reinforcement varied between 40mm and 80mm in the piers depending upon their age of construction with newer piles having the higher cover.

- Cement content varied from 12.8 to 17% by weight with an average of 14.2%.

- The chloride content at the level of reinforcement was higher than general industry accepted lower threshold of 0.06% by weight of concrete for plain steel and 0.03% by weight of prestressed steel. Maximum chloride values of up to 0.32% were measured.

- Visual inspection indicated minor pitting in the reinforcement at selected breakouts but no cracking of concrete as yet. There were also isolated cases of concrete cracking and rust staining on piles.

It was concluded that cathodic protection was required on the existing structures to ensure a remaining life of at least 50 years without significant maintenance.

A hybrid cathodic protection system (HCP) has been designed and commissioned for both the Causeway and the adjacent Whau bridges.

The HCP system comprises discrete zinc anodes which were installed on both the reinforced and prestressed concrete piles from Lowest Astronomical Tide (LAT) level up to the soffit of the crossbeams. The anodes operate in two phases, initially energised using low voltage DC power to arrest ongoing corrosion and thereafter in galvanic mode to provide corrosion prevention for the residual service life. HCP minimised physical works on site, negated the requirement for extensive replacement of chloride contaminated concrete, allowed work to take place accommodating incoming and outgoing tides and offers protection against chloride induced corrosion to the substructures.

8. DISCUSSION AND CONCLUSIONS

Experience has clearly shown that there are some key factors that contribute to the corrosion of concrete bridges. These factors include:

- The exposure zone.

- Concrete cover and design detailing.

- Design and construction quality of concrete.

Experience has also shown that there are significant unexplained differences in real life that can result in durability performance that is significantly better or worse than would initially be predicted.

However they may be at least partially explained by concrete quality, construction quality and exposure micro climates.

Corrosion of reinforced concrete in NZ bridges is generally obvious and takes many years before significant structural deterioration occurs that might impact on the structural performance of the bridge.

Traditional inspection regimes will identify corrosion and a reactive remediation programme is a low risk and good value option in most circumstances.

Corrosion of pre and post tensioned reinforcement is potentially less obvious and can result in significant structural deterioration in a relatively short period of time. Such corrosion therefore has an inherently higher risk in terms of consequences. It is also more difficult and costly to remedy. Therefore a more proactive approach to identification and management of this corrosion is warranted.

In cases where longer term durability performance is required and corrosion has already initiated then cathodic protection techniques provide potentially viable solutions.

9. PHOTOGRAPHS

9.1 Tiwai Point Bridge

9.2 Boundary Creek Bridge

9.3 Fox Bridge

9.4 Ngakawau Bridge

9.5 Mangere Bridge

9.7 Tutaekuri Bridge

9.8 Whirokino Trestle Bridge

9.9 Kopu Bridge

9.10 Hamanatua Bridge

10. REFERENCES

Freitag, S. A. and Bruce, S.M. (2010), The influence of surface

treatments on the service lives of concrete bridges, NZTA Research Report No

403, Wellington, New Zealand.

Bruce, S.M., McCarten, P.S., Freitag, S.A. and Hasson, L.M. (2008),

Deterioration of Prestressed Concrete Bridge Beams. NZTA Research Report 337,

Wellington, New Zealand.

Rogers, R., Al-Ani, M. and Ingham, J.M. (2013), Assessing

Pre-tensioned Reinforcement Corrosion within the New Zealand Concrete Bridge

Stock. NZTA Research Report No 520,

Wellington, New Zealand.

Lee, N. (2017), New Zealand Experiences with Concrete Service Life

Prediction Models: A Brief History, Brian Cherry International Concrete

Symposium, Melbourne, 26 & 27 July, In. Reinforced Concrete Corrosion,

Protection, Repair & Durability, ed. W K Green, .F G Collins and M A

Forsyth, Australasian Corrosion Association Inc., Paper No. 6.

11. AUTHOR DETAILS