Question: It’s been suggested I’ve got lead-containing paint on my structure. What do I do?

Answer:

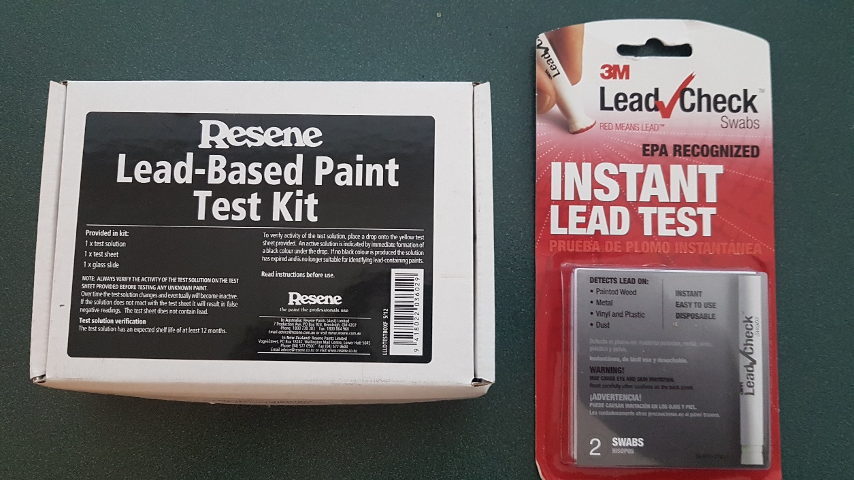

The first thing to do, is to confirm the actual presence of lead using a chemical test kit such as those available from Resene as pictured here;

One uses a 5% w/v solution of sodium sulphide and the method is to place a drop onto a fresh cut in the coating that exposes the primer. If lead pigments are present, a precipitate of black lead sulphide is formed. It should be noted that the solution needs to be fresh (indicated by a rotten egg smell), and that results can be ambiguous on wet substrates and where iron oxides are present. Also, that lead concentrations between 1 and 5% will result in a colour change to various intensities of grey with a change to black where >5%.

The more sensitive 3M ‘Lead-Check’ product uses a mix of chemicals, including sodium rhodizonate plus acid, on a swab that produced a red colouration where lead exceeds 5,000 ppm (0.5% w/w). This can therefore identify surfaces where lead is above the 1% level by weight which was defined in the Standard as a “Lead-containing paint film”.

The relevant Standard to reference is AS/NZS 4361.1:2017, Guide to hazardous paint pigment management, Part 1: Lead and other hazardous pigments in industrial applications (or Part 2: Lead paint in residential, public and commercial buildings).

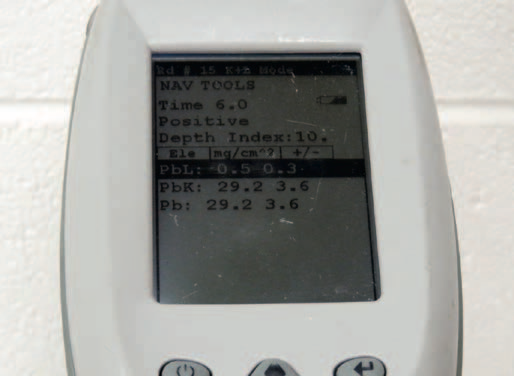

To comply with these Standards, both spot test methods still need more accurate testing to confirm a negative test. This should be by laboratory chemical analysis or by the use of XR Fluorescence Analysers (pictured).

This Q & A was submitted by Willie Mandeno and first appeared in the ACA NZ Branch Newsletter August Edition 2021