Authors: G. Will, S. Denman, M. Rahman, J. Davies

This paper was presented at Corrosion & Prevention 2023.

ABSTRACT

The significance of materials degradation rate and its ensuing repercussions has played a paramount role in human progress. As a result, corrosion has been studied for hundreds of years and with the evolution of technology an increased understanding of the mechanisms and development of new materials has occurred. A foundational understanding of the corrosion process and its effective management is essential for the successful utilization of materials and the application of corrosion prevention methods. The type of material, its history, and the environment should be considered wholistically to predict the degradation mechanisms and rate. Electrochemistry has traditionally been a key to unlocking the mechanisms and rates of corrosion reactions and advances in electronics and data analysis can be used to improve accuracy and educate future generations. At the industrial scale corrosion of assets is often assessed via inspections relying on images and other tools to determine current state of the material. Consolidation of material performance for a particular asset into a model which can learn and provide clear advice to maintainers and asset owners would be of great benefit. With increased data capabilities and analysis techniques utilisation of a broader data set and diverse range of expertise is now becoming more available to those responsible for materials longevity.

Keywords: Corrosion, data analytics, management, materials

Introduction

Percival Faraday Thompson (PFT), (1885-1951), was a metallurgist and analytical chemist who left a lasting imprint on much of modern science, philosophy and specifically the field of corrosion (Potter 1972). Identified as a corrosion pioneer in Australia and around the world, he had the great ability to work in many areas of science and like the great scientists had many insightful observations outside this realm. He was noted as great communicator and educator and it is this legacy we should embrace at every opportunity. He was not afraid to challenge and catalyse healthy debate around fair reaching topics many of which are preserved in his publications and subsequent reviews (Green 2015). These publications make for very entertaining and thought-provoking reading and some of these timeless learnings will be used to guide the following paper.

Briefly, PFT worked in a range of capacities as a chemist at the Working Men’s College, Melbourne University, President of the Society of Chemical Industry of Victoria and the forerunners of both CSIRO and DSTG. As mentioned, many times it seemed destiny by virtue of his middle name, Faraday, that he would succeed in electrochemistry and corrosion with many notable scientific and industrial contributions in gold processing, lead, lubrication, aluminium, cost of corrosion, flow assisted corrosion, microbiological corrosion (MIC) and stress corrosion cracking were made. What prompts reflection from these papers were the incites and challenges he posed to the community at large that still resonate in our current day. The importance of learning from the past was an area PFT wrote about and a specific example being his history of analytical chemistry. He stood on the shoulders of those before him, doing so in a way which was thought provoking and entertaining. He was notably fond of rigorous productive debate and demonstrations and saw the value in groups like the Australasian Corrosion Association (ACA).

PFT was an educator with far reaching impact and vison, utilising “Corrosion Charts” which indicated areas of stability of a metal as a function of electrochemical potential which put him in line early on with the likes of Pourbaix. Also of note was his scepticism for standards and automatic analysis where he wrote “standard methods indicate a loss of that independence of thought which should be the most sacred possession” (Thompson 1932). Standards have their place to provide a basis of quality or practice but should not be a substitute for knowledge and stifle curiosity. He expressed his thoughts on the lack of chemistry knowledge in the engineering sector, yet the use of materials which undergo chemical degradation is a primary focus of their work. This is still a common sentiment but difficult to address with the extremely large breadth of competing knowledge required by engineers.

More broadly he wrote, “Around no subject of technical interest have prejudice and wrong thinking in the past, so wrapped a web of obscurity as that of the corrosion of materials”. Even in current day, myths exist around the use of corrosion prevention techniques under given conditions that cannot be supported by the available science or industry experience. This has been reflected in a 2005 ACA conference paper “Junk Science in Corrosion Control: Gimmicks Gadgets and Gizmos” by the late Mark S. Schilling. (Shilling 2005) and should be the responsibility of corrosion professionals to increase awareness and focus on proven corrosion prevention techniques. PFT was clearly a man of great talent and insight with a generosity for educating and a thirst for knowledge who the great Edmund Potter commented “both international acclaim and conscious retirement eludes PFT, and he enjoyed no more than a languid waning of technical toil”. (Potter 1972)

Discussion

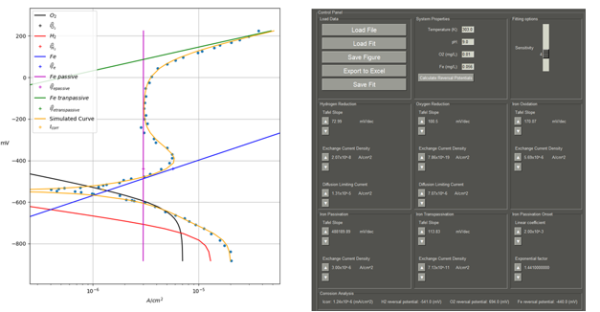

Based on the legacy that PFT has provided the basic electrochemistry surrounding iron will be examined and how modern data analysis and modelling can provide both better interpretation of data and increase the education of electrochemistry and the corrosion process. This work is an extension of a previous PFT lecturer Paul Schweinsberg in conjunction with Harvey Flitt (Schweinsberg 2005) where polarisation curves are deconvoluted into the individual reactions extracting kinetic, thermodynamic and cell characteristics. Figure 1 below shows the experimental data (dots) and the model fit to the data depicting the energetics (voltage) and kinetics (current) for each individual reaction occurring at the electrode surface. Modern computing and the accessibility to advanced modelling techniques has resulted in more advanced solutions which can not only supply better and more insightful results but educate users in the chemical reactions behind a specific system. PFT indicated the importance of educating and understanding the corrosion process and this can be accomplished by experimenting with the cell parameters to achieve changes in the theoretical curve and the goodness of fit.

Figure 1: Modern Symadec showing a polarisation curve for iron in an environment which promotes passivation. Dots are the experimental data; yellow curve is the fit to the data and other curves are the individual reactions and processes indicated.

Although increased knowledge of electrochemistry and corrosion science will assist in the better preservation of assets, in the field the non-ideal and time-based behaviour needs to be considered. Effective asset management is a major contributor to a sustainable future and this idea is often not articulated in discussions of renewable energy and carbon footprints. Conserving assets is something that the corrosion community has been doing for many years and now with the increase in the use of Life Cycle Assessments (LCA) this will become more transparent. (Atkins 2021) The embodied energy in popular construction materials gives one a scale for energy and equivalent CO2 in modern structures which would be lost if not cared for properly, Table 1.

Table 1: Embodied energy, water and emissions for common building materials. (http://epicdatabase.com.au/)

| Material | Energy (MJ/kg) | Water (L/kg) | GHG emissions (kg CO2e/kg) |

| Stainless steel | 97.6 | 140 | 7.2 |

| Steel pipe | 42.9 | 78 | 3.5 |

| Concrete 32 MPa | 1.1 | 1.8 | .18 |

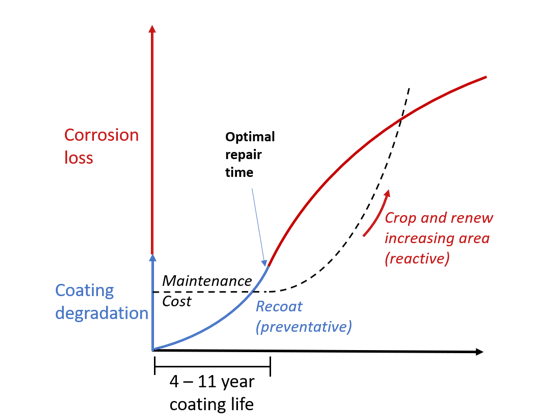

The definition of corrosion refers to the degradation of all materials and much of our industry employs polymers as protective coatings. Protective coatings often define a structures life or at least its time to first or significant maintenance, Figure 2.

Figure 2: Coating degradation and corrosion loss as a function of time for a typical engineering asset.

It is clear from this discussion that many factors and data streams are required to determine the current and future state of an asset. This provides a challenge for data scientists and corrosion practitioner but also presents opportunities to explore the ideal format for asset reporting and evaluation. One could imagine data bases developed for a structure which include build information, geometries, QC reports, exposure conditions, inspection reports, repair data, financials, and availabilities along with the actual and modelled degradation rates of every point on the structure. Each piece of data provides different information in a variety of forms which all contribute to the managing an asset and are often lost or difficult to assimilate. The challenge presents opportunities to link data through various modelling methods to provide current state and future predictions of an asset ultimately populating a precision reality twin for visualisation and decision making.

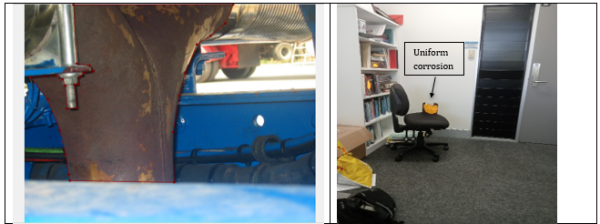

Taking this one step further in the current age of artificial intelligence (AI) one could see the learning of previous assets informing both the manufacture and management of the future. Literature and standards currently are guides currently, but a supervised more integrated approach will assist decision makers to better outcomes. This is already being done with image analysis and autonomous inspections (eg. Abyss Solutions, Trendspek, SpotRust) (Nash 2022) where expert knowledge is used to continuously train and improve neural networks, Figure 3. The incorporation of expert knowledge is vital in guiding the AI, which can remove menial tasks, direct efficient inspection, and highlight difficult to identify features which can be used to augment decision making. AI needs to be trained and mentored by experts and the knowledge gained can be used to educate the next generations and provide a basis of future innovation. It is hoped that this would influence all stages of the asset’s life informing initial design, fabrication, surface preparation, coating application, QC, coating failure and the onset identification and progress of degradation. Recently, physics informed AI is attempting to bring the underlying science and engineering models into training the neural networks, allowing smaller training sets to generate accurate results and predict future state (Zhu 2023).

Figure 3: Training image part of a larger training set (left). Identified uniform corrosion using semanitic segmentation (right).

With advances in drone technology and lidar scanning one can envisage autonomous inspection of assets particularly for confined space and hazardous areas which provide accurate area, volume and displacement changes associated with environmental and mechanical degradation. The results can used to make decisions but also after validation be included as training for the next iteration of the model such that continuous improvements are made.

Conclusions

The prevention of corrosion can benefit from the available data to understand, mitigate, and evaluate its progress. The collection, analysis, modelling and prediction capabilities available for these large data sets allows us to learn more about corrosion management, highlight short comings at the point of design and understand the implications of decisions on the overall life of an asset.

These are exciting times whereby the expertise of current and past practitioners and assets can be used to educate the workforce and manage materials systems in the complexed world of corrosion more efficiently. The fear of technology is an age-old concern but as with previous advances, AI will used as a tool to educate, facilitate decision making, improve efficiency and augment current capabilities.

References

- Potter EG, The corrosion scene in Australia, Australasian Corrosion Engineering, March, (1972) 21-29.

- Green W, Hinton B, P F Thompson – Australia’s pioneer in corrosion research and education (2015) p. (available at https://hdl.handle.net/10536/DRO/DU:30081795).

- Thompson PF, The case against standardisation of chemical analysis, Chem Eng. Mining Rev. (1932) 31-32.

- Shilling M, Junk Science in Corrosion Control: Gimmicks Gadgets and Gizmos, ACA conference proceedings 2005 (sourced on 16/10/23 from http://toc.proceedings.com/15630webtoc.pdf).

- Flitt H J, Schweinsberg D P, Evaluation of corrosion rate from polarisation curves not exhibiting a Tafel region, Corrosion Science 47 (2005) 3034–3052.

- Atkins C, Lamber P, Sustainability and corrosion, (2022) 175(1), pp. 22–29, Proceedings of the Institution of Civil Engineers – Engineering Sustainability. https://doi.org/10.1680/jensu.21.00011.

- Nash, W., Zheng, L. & Birbilis, N. Deep learning corrosion detection with confidence, (2022) Mater Degrad 6, 26. https://doi.org/10.1038/s41529-022-00232-6.

- https://abysssolutions.co/case-studies/atmospheric-corrosion-detection-and-management-with-artificial-intelligence, accessed 16/10/23.

- https://trendspek.com/, accessed 16/10/23.

- Shun-Peng Z, Lanyi W, Changqi L, José C, Abílio D J, Filippo B, and Qingyuan W, Physics-informed machine learning and its structural integrity applications: state of the art (2023) Phil. Trans. R. Soc. A. 381:2022040620220406 http://doi.org/10.1098/rsta.2022.0406.

Author Details

| Assoc. Prof. Geoffrey Will has been a member of the ACA for over 22 years. Previously working at Queensland University of Technology for 23 years he has recently taken a position at the University of The Sunshine Coast. He has co-authored 177 papers in materials, electrochemistry, and molten salt corrosion. He serves on ASTM standards committee and consults to industry. His group developed techniques to monitor coating breakdown and models to predict corrosion behaviour. In the last 10 years his efforts supported high temperature solar thermal implementation. |

| Dr Simon Denman is a Senior Lecturer in the School of Electrical Engineering and Robotics at Queensland University of Technology (QUT). Simon actively researches in the fields of computer vision and machine learning, including action and event recognition, trajectory prediction, video analytics, biometrics, and medical signal processing. Simon has published over 140 papers in the areas of computer vision and machine learning, and co-leads the Applied Data Science research programme within the QUT Centre for Data Science. |

| Mr. Joseph Davies specialises in corrosion management and analysis. Take a holistic approach to corrosion prevention that incorporates testing and monitoring of structural components so that important assets can be managed more optimally. My doctoral research pursues a better understanding of the degradation of organic coatings for corrosion prevention using inspection records, enhanced laboratory testing and in field condition monitoring. |

| Dr Mohammad Mahfujur Rahman is a Research Fellow in Signal Processing, Artificial Intelligence and Vision Technologies (SAIVT) in the School of Electrical Engineering and Robotics at QUT. He received his PhD degree in computer vision and deep learning from QUT. Dr Mahfujur research is in the fields of computer vision and machine learning, transfer learning, domain adaptation, domain generalisation, object detection, classification and image segmentation. He aims to utilise AI to enable visual learning. |