Credits: Willie Mandeno (Mandeno Consulting Ltd).

Abstract: This paper discusses and compares the different pre-coating of steel surface cleanliness standards for hand and power tool, wet and dry abrasive blasting, and water jetting prepared by ISO, SSPC, & NACE, with the AS 1627 series of Standards. It updates an earlier version of this paper was published in the April 2003 issue of the ACA Journal ‘Corrosion and Materials’.

1. INTRODUCTION

The performance of structures depends to a large degree on the adequacy of their foundations. Protective coatings are no different, and what is under a coating can be just as important as what is in it. A UK Corrosion Committee demonstrated over 70 years ago that the prior removal of mill scale by abrasive blasting more than doubled the life of oil-based paint on steel.

This paper discusses and compares the commonly used Australian, European and North American Standards that can be specified to ensure that the potential long life of a modern protective coating system will not be compromised by inadequate surface preparation. The three critical factors in surface preparation are;

- Removal of visible contamination

- Removal of invisible contamination

- Adequate surface profile

VISIBLE CONTAMINATION

2.1 History

Standards to specify the level of cleanliness of steel after abrasive blasting appeared after World War II in various forms. In 1952 the Steel Structures Painting Council (SSPC) in the USA published the following series of tentative specifications (with latest publication dates given in brackets);

SP 1 Solvent Cleaning (2016)

SP 2 Hand Tool Cleaning (2018)

SP 3 Power Tool Cleaning (2018)

SP 4 Flame cleaning of New Steel (Discontinued in 1982)

SP 5 White Metal Blast Cleaning (/NACE No.1 -2006)

SP 6 Commercial Blast Cleaning (/NACE No.3 -2006)

SP 7 Brush-Off Blast Cleaning (/NACE No.4 –2006)

SP 8 Pickling (2004)

SP 2 & SP 3 were defined in the original standard as cleaning at a rate of 2 sq ft/min after removal of grease and rust scale, while SP 6 was an end product achieved under standard conditions. All were formally adopted in 1963, except that SP 6 was amended to be a descriptive specification (ie. >2/3rds of the metal surface to be clean of rust and mill scale), and the following new specs were published;

SP 9 Weathering followed by blast cleaning (Discontinued in 1971)

SP 10 Near-White Metal Blast Cleaning (>95% clean) (/NACE No.2- 2006)

SSPC VIS 1 Guide and Reference photographs for Steel Surfaces Prepared by Dry Abrasive Blast Cleaning

SSPC VIS 1 was originally based on the series of photographs and text (in six languages) first published in 1962 as Svensk (Swedish) Standard SIS 05 59 00, “Rust grades for steel surfaces and preparation grades prior to protective coating”. This latter document was developed by the Swedish Corrosion Institute in cooperation with ASTM and SSPC and was endorsed by Standards Australia and republished as AS CK9.4-1964. This was revised and redesignated as AS 1627.9 in 1974. SIS 05 59 00 has been adopted as the basis of several other international Standards used for visual assessment of cleaned surfaces including; ASTM D2200-67, BS 7079-A1:1989, DIN 55 928.4 & ISO 8501-1. The second edition of AS 1627.9 was published in 1989 as an endorsed copy of ISO 8501-1:1988. The recently republished third edition AS 1627.9:2002 (reconfirmed 2017) now contains no photos and “provides requirements for the designation of rust grades and the definition of preparation grades of steel surfaces by reference to ISO 8501-1:1988”.

ISO 8501-1:2007 ‘Preparation of steel substrates before application of paints and related products – Visual assessment of surface cleanliness – Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings’ is an A5 book which incorporates 24 photos from SIS 05 59 00, plus four photos from DIN 55 928.4 that show the 4 rust grades “prepared by so-called flame cleaning”. This ISO Standard (which is also the fourth edition of Swedish Standard SS 05 59 00) now defines surface preparation by the written descriptions with the photos being representative examples, which is a change from previous editions where the preparation grades were defined by the photographs. This visual Standard was first published in 1988.

SSPC surface preparation standards were revised again in 1987 when SP 11 (Power Tool Cleaning to Bare Metal) was introduced (latest issue date is 2020). Other joint SSPC/NACE standards have since been published and these are listed below with their latest issue date;

SSPC-SP 12/NACE No. 5, Surface Preparation and Cleaning of Steel and Other Hard Materials by High- and Ultrahigh-Pressure Water Jetting Prior to Recoating (1995)

SSPC-SP 13/NACE No. 6, Surface Preparation of Concrete (2018)

SSPC-SP 14/NACE No. 8, Industrial Blast Cleaning (2006)

SSPC-SP 15, Commercial Grade Power Tool Cleaning (2013)

SSPC-SP 16, Brush-Off Blast Cleaning of Coated and Uncoated Galvanized Steel, Stainless Steels, and Non-Ferrous Metals (2020)

SSPC-SP 17, Thorough Abrasive Blast Cleaning of Non-Ferrous Metals (2019)

SSPC-SP 18, Thorough Spot and Sweep Blast Cleaning for Industrial Coating Maintenance (2020)

These surface preparation standards are now managed by and are available from the Association for Materials Protection and Performance (AMPP) at http://www.ampp.org

2.2 Visual Standards of Cleanliness

Standards based on SIS 05 5900 all describe four different initial conditions of surface;

A = “covered completely with adherent mill scale and with little if any rust.”

B = “begun to rust and from which the mill scale has begun to flake.” (Typical of new steel after 2-3 months at Gothenburg port)

C = “mill scale has rusted away or from which it can be scraped, but with little pitting visible to the naked eye.” (1+ year exposure)

D = “mill scale has rusted away and on which considerable pitting is visible to the naked eye.” (~3 years marine exposure)

The 1962 edition of SIS 05 5900 described surfaces prepared by manual tool cleaning as;

St 0 = No preparation of surface

St 1 = Light wire brushing (every part brushed twice)

St 2 = Thorough scraping followed by wire brushing to give a “faint metallic sheen”.

St 3 = Extremely thorough scraping (in two directions) and wire brushing to give a “pronounced metallic sheen”.

Also surfaces cleaned by abrasive blasting were described as;

Sa 0 = No preparation of surface

Sa 1 = Light blast cleaning so that loose material is removed.

Sa 2 = Thorough blast cleaning to “remove all mill scale and rust and practically all foreign matter.”

Sa 3 = Blast cleaning to white metal to “remove all mill scale, rust and foreign matter.”

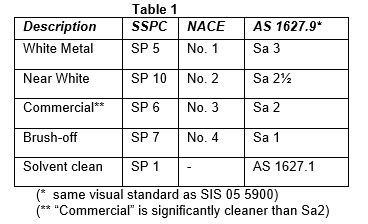

In 1967 the Swedish Standard was revised and re-issued with a new grade ‘Sa 2½’ corresponding to the new intermediate grade SSPC-SP10. ‘St 3’ became “Very thorough” scraping, ‘St 1’ was deleted (as this condition is considered unsuitable for painting), and other descriptors had minor changes. Relationships between the main standards then are shown Table 1 below.

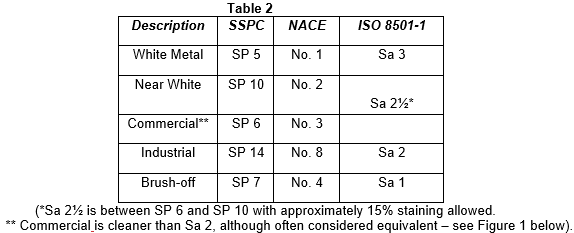

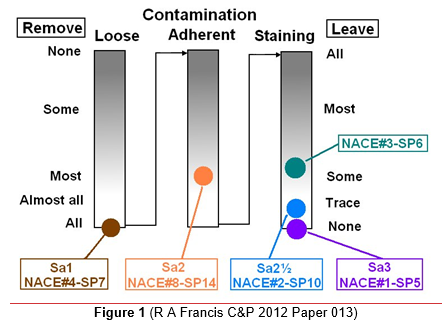

SSPC-VIS 1 was republished in 1989 using different photos to SIS 05 5900 which better matched SSPC’s own written descriptions. VIS 1 was then republished again in 2002, revised in 2012 and now includes photos of previously painted steel plates (Condition G) that have been abrasive blasted and a pictorial reference for SSPC-SP 14. Relationships between the current standards are shown in Table 2.

Also included are photos of surfaces prepared using different metallic and non-metallic abrasives (now also covered by the 1994 supplement to ISO 8501-1), and an appendix showing the effect of variations in profile and lighting angle. Condition G is defined as follows;

G = Thoroughly Weathered, Blistered or Stained coating over Mill scale

G1 = with Extensive pinpoint rusting

G2 = with Moderate pitting

G3 = with Severe pitting

Previously painted steelwork is also covered by BS 7079-A2: 1996/ ISO 8501-2:1994 Part 2:’Preparation grades of previously coated steel substrates after localized removal of previous coatings’ where the ‘Sa’ and ‘St’ grades are prefixed with ‘P’ indicating “only localised removal of the previous paint coating”.

Photographic standards of cleanliness are now also available for assessing surfaces cleaned by high and ultrahigh pressure water jetting to SSPC-SP 12/NACE No.5. This is SSPC-VIS 4/NACE VIS 7 and for wet abrasive blast cleaning, SSPC-VIS 5/NACE VIS 9 should be used. These are discussed further in Sections 2.5 & 2.6 of this paper.

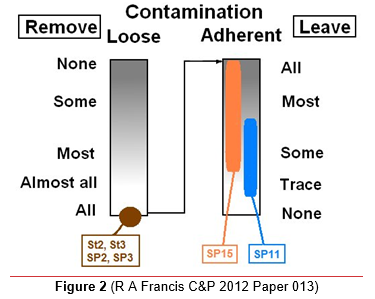

2.3 Hand and Power Tool Cleaning

SSPC-SP 2 & SP 3 are approximately equivalent to St 3 in the Swedish Standard, and SSPC-SP 11 (which requires a minimum profile of 25 microns) is approximately equivalent to Sa 2½. The more recent SSPC-SP 15 is a “commercial” power tool cleanliness standard that is cleaner than SSPC-SP 3 and also requires a minimum profile of 25 microns to be retained or produced. It is different to SP 11 in that stains of rust, paint or mill scale may remain on the surface and has been described a power tool “equivalent” of SSPC-SP14 / NACE No. 8. The associated visual standard is SSPC VIS 2 (2008).

These cleaning procedures were also respectively specified by AS 1627.2-1989 and AS 1627.7-1988 (that originated as AS CK9.2 & 9.7-1967) but these Standards have now been withdrawn and replaced by AS 1627.2-2002 (R2017), Power tool cleaning, which was identical with ISO 8504-3:1993, Surface Preparation Methods Part 3: Hand- and Power-tool cleaning which references ISO 8501 Parts 1 & 2 for visual cleanliness. See Figure 2 for comparison.

2.4 Dry Abrasive Blasting

Often coating specifications only cover the first critical factor by requiring abrasive blasting to a nominated standard of cleanliness. Care is required to refer to the actual wording used to specify the description of the surface appearance, which may be slightly different between specifications of different years and also from different agencies. Also be aware that appearance will be affected by both the initial rust grade of the steel and the type of abrasive used.

Previous editions of AS 1627.4 defined four classes of surface preparation as follows;

Class 1 – Light Blast Cleaning “such that loose mill scale, loose rust, and foreign particles are removed.” (approximates Sa 1)

Class 2 – Medium Blast Cleaning “such that mill scale, rust, and foreign particles are substantially removed and grey metal is visible.” (approximates Sa 1)

Class 2½ – ‘Near White Blast Cleaning “such that mill scale, rust, and foreign particles are removed to the extent that the only traces remaining are slight stains in the form of spots or stripes.” (approximates Sa 2½)

Class 3 – ‘White Metal’ Blast Cleaning “such that all mill scale, all rust, and all foreign particles are entirely removed. The cleaned surface shall have a uniform metallic colour.” (approximates Sa 3)

A variety of media other than the traditional chilled iron and steel grit or crushed garnet can be used for abrasive blasting, such as crushed glass, iron slag or basalt, and silica free iron sand. These are described in AS 1627.4-2005 (R2017). An earlier 2002 version of this standard was identical with, and was reproduced from, ISO 8504-2:2000, but this was withdrawn and a new standard prepared, according to the preface as a “result of requests from Australian Industry who were not satisfied with the previous adoption of ISO 8504-2:2000”. Quartz river sand is no longer permitted by Health & Safety restrictions on the free crystalline silica content of abrasive media to minimise the risk of the respiratory disease of silicosis. (In NZ the maximum allowed is 2%, which includes an allowance to compensate for measuring accuracy). Other less common media range from the very hard aluminium-oxide to specially treated sodium bicarbonate that is soft enough to remove paint a layer at a time.

Where abrasive blasting is not permitted or possible, other cleaning methods and grades of preparation can be specified using Part 0 (1997) ‘Method selection guide’ and the other parts of the NZ/AS 1627 series of Standards, ‘Metal finishing – Preparation and pre-treatment of surfaces’ that includes or included;

Part 1 Cleaning using liquid solvents and alkaline solutions (third edition issued in 2003)

Part 2 Power tool cleaning (2002 edition is identical with ISO 8504-3)

Part 3 Flame descaling (withdrawn)

Part 5 Pickling, descaling and oxide removal (third edition issued in 2003)

Part 6 Chemical conversion treatment of metals (third edition issued in 2003)

Part 7 Hand tool cleaning (discontinued in 2002 when combined with Part 2)

Part 8 Wash primer pre-treatment (withdrawn and superseded first by AS 3884 and subsequently by AS/NZS 3750.17))

Part 9 Pictorial surface preparation standards (2002 edition is identical with ISO 8501-1)

Part 10 Cleaning using acid solutions (non immersion) (withdrawn 1999)

Note: The non-withdrawn Parts were all reconfirmed in Australia in 2017 and remain current in New Zealand.

2.5 Wet Abrasive Blasting

In 1998, the Joint Technical Report SSPC-TR 2/NACE 6G198 was published. This covers the procedures, equipment, and materials involved in a variety of air/water/abrasive, water/abrasive, and water-pressurised abrasive blast cleaning systems.

SSPC-VIS 5/NACE No. 9, ‘Guide and Reference Photographs for Steel Surfaces Prepared by Wet Abrasive Blast Cleaning’ was published in 2006. This illustrates the appearance of surfaces with Initial Condition C & D before and after cleaning as described in SSPC-TR2/NACE 6G198, which immediately after cleaning are comparable in the degree of staining permitted to SSPC-SP 6 (also designated NACE WAB-3) & SSPC-SP 10 (designated NACE WAB-2). Also shown are conditions to be specified immediately prior to coating with 3 different levels of flash rusting (ie Light, Moderate, and Heavy).

The full set of applicable Standards with current titles are listed below;

SSPC-SP 5 (WAB)/NACE WAB-1 -2015 White Metal Wet Abrasive Blasting

SSPC-SP 6 (WAB)/NACE WAB-3 -2015 Commercial Wet Abrasive Blasting

SSPC-SP 7 (WAB)/NACE WAB-4 -2015 Brush-Off Wet Abrasive Blasting

SSPC-SP 10 (WAB)/NACE WAB-2 -2015 Near-White Metal Wet Abrasive Blasting

SSPC-SP 14 (WAB)/NACE WAB-8 -2015 Industrial Wet Abrasive Blasting

2.6 Water Jetting

SSPC-SP 12/NACE No. 5, ‘Surface Preparation and Cleaning of Steel and Other Hard Materials By High- and Ultra-High Pressure Water Jetting Prior to Recoating’, was first published in 1995, then revised in July 2002, and is proposed to form the basis of a new Part 11 of AS/NZS 1627. This avoids such poorly defined terms as ‘water-blasting’ and ‘hydro blasting’ and introduced the term ‘water jetting’ where nozzle pressures are >700 bar.

The original SSPC/NACE classifications of the different pressure ranges have been adopted in Section 4 of the 2002 version of AS/NZS 2312, and are reproduced below;

Low-pressure water cleaning (LPWC) 20 – 35 MPa (3,000 – 5,000 psi)

High-pressure water cleaning (HPWC) 35 – 70 MPa (5,000 – 10,000 psi)

High-pressure water jetting (HPWJ) 70 – 170 MPa (10,000 – 25,000 psi)

Ultra-high-pressure water jetting (UHPWJ) > 170 MPa (25,000 psi)

The July 2002 revision of NACE No.5/SSPC-SP 12 and 2014 revision of AS/NZS 2312 have now increased the difference between HPWJ and UHPWJ from 170MPa to 210MPa (30,000 psi). Four visual conditions are defined which describe the surface (when viewed without magnification) ranging from WJ-1 (equivalent to NACE No.1 but with “a matte metal finish”) to WJ-4 (equivalent to NACE No.4). Also defined were three levels of non-visual conditions as summarised below;

NV-1 Free of water-soluble chlorides, iron-soluble salts, and sulfates as determined by field testing.

NV-2 <7 μg/cm2 chlorides, < 10 μg/cm2 ferrous irons, and < 17 μg/cm2 sulfate contaminates

NV-3 <50 μg/cm2 chlorides and sulfate contaminates

NACE No.5/SSPC-SP 12 was superseded in 2021 by Standards that specified the four different levels of cleanliness and leave the choice of pressure to the Contractor. These are;

NACE WJ-1/SSPC-SP WJ-1, Waterjet Cleaning of Metals – Cleaning to Bare Substrate (WJ-1)

NACE WJ-2/SSPC-SP WJ-2, Waterjet Cleaning of Metals – Very Thorough Cleaning (WJ-2)

NACE WJ-3/SSPC-SP WJ-3, Waterjet Cleaning of Metals – Thorough Cleaning (WJ-3)

NACE WJ-4/SSPC-SP WJ-4, Waterjet Cleaning of Metals – Light Cleaning (WJ-4)

SSPC-VIS 4/NACE VIS 7, ‘Guide and Reference Photographs for Steel Surfaces Prepared by Waterjetting’ was first published as an interim standard in 1998 and then republished in 2005. This illustrates the appearance of Rust Grade C & D surfaces cleaned according to SSPC-SP 12, which immediately after cleaning are comparable in the degree of staining permitted to SSPC-SP 6 (“Thorough Cleaning” designated Vis WJ-3) & SSPC-SP 10 (“Very Thorough Cleaning” designated Vis WJ-2). Also shown are conditions to be specified immediately prior to coating with 3 different levels of flash rusting as in VIS 5 (ie Light, Moderate, and Heavy). It is noted “steel surface produced by water jetting do NOT look the same as those produced by dry or wet abrasive blasting. This is because water on its own cannot cut or deform steel like abrasives.”

ISO 8501-4:2020 Initial surface conditions, preparation grades and flash rust grades in connection with water jetting can also be used for the visual assessment of surface cleanliness after water jetting. It also covers four cleanliness standards but with different designations as shown below that are roughly equivalent to the ‘Sa’ dry blasting standards.

Waterjetting to Bare Substrate (Wa 3)

Very Thorough Waterjetting (Wa 2½)

Thorough Waterjetting (Wa 2)

Light Waterjetting (Wa 1)

2.7 Rust ‘Conversion’

An alternative to rust removal that is often touted is the use of so called ‘rust converters’ or ‘rust stabilisers’. These are chemicals, often based on tannic or phosphoric acid, which are applied to rusted surfaces and are claimed to convert the rust into a more benign form, make it adhere strongly to the surface, or otherwise provide a suitable surface for paint application. However, the Standard Guide AS/NZS 2312 notes there is considerable evidence to refute these claims. It recommends the use of conventional products such as inhibited alkyd primer or “surface tolerant” epoxy mastic for hand-cleaned rusty steel, and states that the use of ‘rust converters’ with these systems is “not recommended, and will detract from their subsequent performance”.

NON-VISIBLE CONTAMINANTS

The importance of non-visible contaminants on a steel surface as a cause of premature coating breakdown was recognised by the publication of AS/NZS 3894.6:1996. This joint Standard gave two methods for determination of chloride levels. Also covered are standard tests for oil and water droplets, surface dust, soluble salts of iron, and mill scale. Refer also to AS 2312.1 para 4.3.

AS 1627.4:2005 (R2017) requires surface cleanliness be assessed in accordance with AS 3894.6-2002(R2013). Also recommended is ISO 8502 ‘Preparation of steel substrates before application of paints and related products – Tests for assessment of surface cleanliness’ which includes several parts including conductometric (Part 9) and titrimetric (Part 10) determination in the field of water-soluble chlorides.

SURFACE PROFILE

This important parameter is often overlooked by some specifiers who assume that just requiring a standard of cleanliness is sufficient. Some methods of cleaning such as pickling or water jetting can produce a very clean surface suitable for electroplating or galvanizing. However, these surfaces will be inadequate for systems such as metal sprayed coatings which are weakly adherent and rely on a degree of mechanical bonding. Profile or surface roughness also provides a larger effective area for adhesive bonding by coatings. On hand prepared surfaces, operators should avoid detrimental burnishing produced by excessive power wire brushing, which will not provide a good key for paint.

As well as depth of profile, the type of abrasive media used can affect the texture. A jagged profile as produced by steel grit is preferred for most high-performance coatings over the peened pattern obtained by shot blasting. Grading of abrasive media is also important to ensure that profile is relatively uniform without ‘rogue peaks’ that can protrude through thin films and lead to premature failure. Weld spatter and slag (and salt-containing welding fluxes) should always be removed first, and it is also good practice to round all sharp edges to a 1.5 to 2 mm radius before abrasive blasting. Flame cut edges should also be ground back by 1 – 2mm to remove surface hardened material in the heat affected zone which may otherwise result in lower surface profile on these edges.

Some coatings such as ultra-high build epoxies and flame-sprayed aluminium or zinc require surface profiles of the order of 75 microns to develop satisfactory adhesion. Where necessary or specified, actual profiles can be measured using a variety of techniques, including a dial surface profile gauge (depth micrometer) or replica tape, all as described in AS/NZS 3894.5. Surface profile may also be assessed in accordance with ISO 8503-1 ‘Preparation of steel substrates before application of paints and related products – Surface roughness characteristics of blast-cleaned steel substrates – Part 1 Specifications and definitions for ISO surface profile comparators for the assessment of abrasive blast-cleaned surfaces and also allows by agreement, assessment in accordance with ISO 8503-2 ‘Method for the grading of surface profile of abrasive blast-cleaned steel. Comparator procedure’. Although some of the SSPC Standards include the requirement that “the surface shall be roughened to the degree suitable for the specified coating system”, the specifier should nominate the profile range required by the system rather than a single figure (impossible to achieve) or simply a minimum profile height.

It is also important to ensure the surface is free of sharp edges or rolling defects such as splinters that could penetrate the coating, and for some paint systems being spray applied, free of narrow pits that the film may not fill. Specifiers should reference one of the three treatment grades given in AS 8501-3:2022 (which adopts and modifies ISO 8501-3 2006 Treatment grades of welds, edges and other areas with surface imperfections). For example, “thorough treatment” grade P3 requires the surface to be free from significant imperfections with edges radiused to >2mm and is recommended for thermal metal spray.

CONCLUSION

Appropriate standards are now available for specification and inspection purposes, and so should be used by all in the protective coatings industry. Surface preparation must be appropriate for the coating system to follow it. High performance primers like inorganic zinc silicate require a grit blasted surface to realise their potential long life, but a wire brushed surface may be adequate for an alkyd system in a mild or interior environment. However merely specifying a visual standard of cleanliness such as ‘Sa 2½’ is not sufficient for a long-term coating system. The surface must also have both an appropriate profile and a suitably low level of non-visible contaminants. Also remember the standard photographs only provide a visual guide, and reference should be made to the actual wording used to define the standard of preparation, which may not be the same as in an “equivalent” Standard.

ACKNOWLEDGMENT: Review of and input into this paper by Dr Rob Francis is gratefully acknowledged.