Authors: A. Dickinson, D. Whitmore

This paper was presented at Corrosion & Prevention 2023.

ABSTRACT

As an alternative to the unsustainable practice of demolition and replacement, a viable option is to repair and protect the severely deteriorated structure utilizing galvanic encasements or jackets that both structurally upgrade and cathodically protect the structure.

This paper presents case studies on the use of galvanic encasements to repair and protect reinforced concrete structures. Long term monitoring of field projects in Australia and overseas over more than 10 years verifies that this is a sustainable and effective long-term concrete repair and cathodic protection solution that can extend the service life of deteriorated concrete structures by 20 to 40+ years.

Keywords: cathodic protection, galvanic encasements, concrete repair, steel corrosion

INTRODUCTION

Reinforced concrete structures can be designed and maintained to achieve long service lives, even in aggressive chloride environments. Unfortunately, many structures, such as bridges, piers, and wharves, show signs of corrosion such as rust staining and concrete spalling in as little as 10 years. Left unchecked, chloride induced corrosion can lead to major structural problems and many severely corroded structures have been demolished and replaced at great financial and environmental expense as well as significant disruption to the public.

Extending the service life of existing reinforced concrete structures is a sustainable practice and provides many benefits to structure owners and society. Direct benefits include cost savings for owners and a general reduction in disruption to the public caused by repair and replacement. Extending service life also provides many indirect benefits including reduction in the use of materials, reduction in the generation of demolition waste, reduction of environmental emissions, and the protection of sensitive habitat and existing ecosystems.

DEVELOPMENT AND MONITORING OF DISTRIBUTED ANODE

Since 1974, impressed current cathodic protection (ICCP) has been used in North America as part of the corrosion protection strategy to rehabilitate corrosion-damaged bridges containing black steel (2). It has been well documented that for ICCP to function properly and arrest corrosion, the systems must be monitored on an ongoing basis. Many transportation agencies, port authorities, and facility owners, either because of a lack of understanding of cathodic protection technology or inability to provide dedicated staff to conduct the required ongoing monitoring and maintenance, simply do not specify cathodic protection rehabilitation of their bridges. The need for ongoing monitoring and maintenance of the current supply is a major challenge for impressed current systems.

Galvanic anode systems can supply sufficient current to provide effective cathodic protection, does not require specialized knowledge for installation and can significantly minimize the need for future monitoring and maintenance.

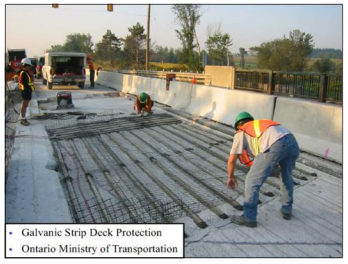

With experience gained through the application of discrete galvanic anodes in patch repairs for corrosion prevention and drilled-in anodes for corrosion control of sound concrete with high corrosion potentials and chloride concentrations, the Ontario Ministry of Transportation (MTO), Ontario, Canada, and Vector Corrosion Technologies conducted a trial using a distributed galvanic anode system (DAS) in a bridge deck overlay to address the global corrosion issues in the structure on 20 September 2003.

Figure 3: First Trial of DAS Anodes in Bridge Deck Overlay, Ontario, Canada, in 2003

The North Otter Creek Bridge is a reinforced concrete structure with a span length of 20m and a roadway width of 8.5m. The bridge was built in 1960 and was first rehabilitated in 1984 with the MTO’s “first-generation” cathodic protection system. The cathodic protection system included an impressed current system consisting of high silicon cast iron anodes in a conductive – asphalt overlay.

A condition survey conducted in 2000 found that the concrete deck (assessed using cores and sawn samples) was in good condition. The core samples extracted from the bridge deck confirmed that the reinforcing steel was also generally in good condition. The compressive strength of the concrete was 36.2MPa and the concrete cover to the top reinforcement ranged from 60 to 135mm and averaged 100mm. The chloride ion content at the level of the mean cover depth (100 mm) was approximately four times higher than the chloride level generally accepted as the threshold to initiate corrosion (0.025% chloride by weight of concrete). The corrosion potential survey was conducted in accordance with the ASTM (C-876), using a copper-copper sulphate reference cell, which indicated that approximately 88% of the concrete deck area had half-cell potential readings more negative than – 0.35V The 3 remainder of the readings were in the uncertain range (- 0.20 to – 0.35V (CSE)). The findings of the condition survey confirmed that the cathodic protection system successfully extended the service life of the deck as evidenced by the good condition of the structure (i.e. no delamination or other corrosion damage in the presence of high corrosion potentials and high chloride levels). However, the previously installed impressed current cathodic protection system had reached the end of its service life.

In September 2003, a new DAS galvanic cathodic protection system was installed at the south end of the bridge to monitor a deck area of about 26 square metres. This consisted of precast anode strips installed at approximately 300 mm centres. Each DAS anode consisted of zinc rods encased in a proprietary cementitious backfill containing lithium hydroxide. The precast DAS anodes measured 12mm by 50mm and were 2440mm in length. Prior to the installation of the anodes, the concrete surfaces were scarified. A carbon fibre mesh was used to prevent or reduce shrinkage cracks in the concrete overlay. Plastic anchors were used to fix the carbon fibre mesh in place prior to the concrete overlay placement.

Four multiple-element probes (MEP) were installed at two locations. At each location, a MEP was placed next to the top and bottom mat of reinforcement. The MEP consisted of a manganese dioxide reference cell, a stainless steel and a mild steel probe, and a connection to the reinforcement.

This arrangement enabled long-term evaluation of reinforced concrete structures and was used to evaluate the effectiveness of a cathodic protection system performance.

The distributed anode system along with the respective instrumentation was terminated in a junction box. Each junction box contained a system on/off switch and a 0.001-ohm precision resistor. This arrangement and the installed MEP allowed the anode current to be measured and the current density generated by the anodes to be evaluated (with respect to concrete surface area). The manganese dioxide reference cell from each probe was used to determine the polarization received by the reinforcement.

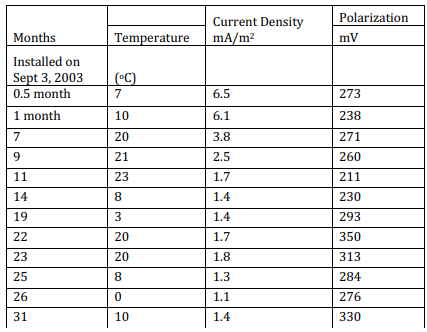

The values were then averaged to determine a polarization value for the system. It should be noted that all the embedded instrumentation was backfilled with concrete containing the typical amount of chloride found in the deck (at the reinforcement level). Except for winter months when the bridge deck froze and current and corrosion potential readings were not reliable, more than sufficient current was being supplied by the anodes to meet the 100 mV criteria generally accepted as indicative of effective cathodic protection (Table 1).

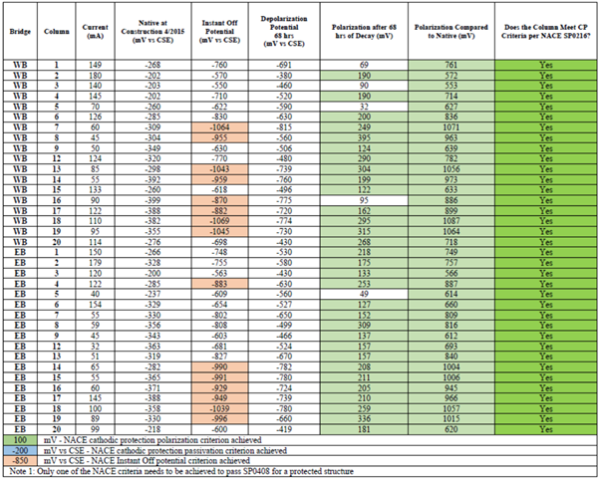

Table 1. Monitoring Data of DAS Anodes

FLORIDA DOT JACKETING WITH DISTRIBUTED ANODES

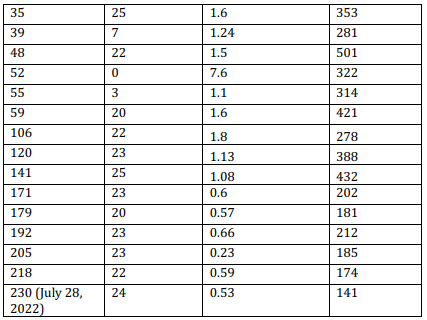

The Lake Avenue Bridge over the Intercoastal Waterway in Lake Worth, Florida is comprised of two bridges, an eastbound and a westbound structure. The Lake Avenue Bridge’s substructure is comprised of flattened oval-shaped reinforced concrete columns supported on footers and piles. The columns measure 4 feet wide by 7 feet long, with 3 feet of flat section in the center and 2 feet of curved sections on each end.

Each of the bridges have 20 piers with a single column at each pier. These Florida DOT marine bridges were suffering from corrosion due to chloride contamination from storm surges and atmospheric exposure. Due to the corrosion deterioration of the columns, galvanic cathodic protection jackets with alkali-activated distributed anodes were installed in 2015 on a total of 36 columns.

The scope of work included the removal of existing 7-foot-high structural steel jackets (Figure 1), removal of deteriorated concrete, and installation of the new cathodic protection jackets of the same height (Figure 4).

Figure 1: Concrete Damage Revealed After Removal of Structural Steel Jackets

Florida DOT typically uses cathodic protection jackets with bulk anodes for concrete pile protection. In this case, the base of the columns are not normally submerged in the seawater, so a different approach was taken. The FDOT specification required that the activated distributed anodes be pre-attached the fiberglass forms at a spacing of 300mm (Figure 2). Welded wire fabric was also installed in the 100mm annular space of each jacket between the pre-attached anodes and the concrete surface. After the concrete fill cured, a potential monitoring access port was installed in each jacket.

Figure 2: Curved Jacket Sections with Pre-Attached Distributed Anodes

Figure 3: Cross section of Jacket 6

Figure 4: New Cathodic Protection Jackets Installed

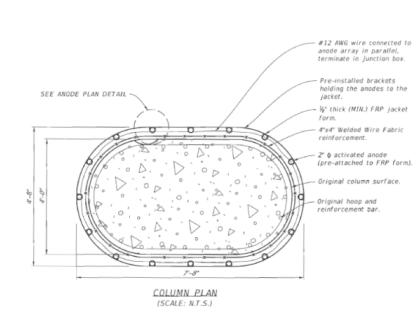

In May 2022, the cathodic protection jackets were evaluated after 7 years of continuous operation (Table 2). The conclusion of the evaluation is that the alkali-activated distributed anodes are performing as intended with the anodes providing sufficient current to polarize the steel rebars, meet the NACE and AS2832.5 cathodic protection standard, and mitigate active corrosion.

Table 2: Performance of Alkali-Activated Distributed Anodes on Marine Columns Above the Tidal Zone 7 Australian and New Zealand Distributed Anode Case Histories

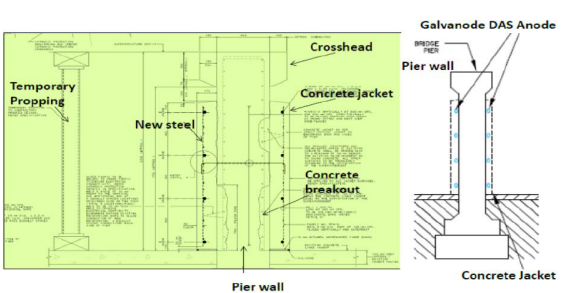

This same technique of using distributed galvanic anodes in galvanic encasements such as abutments, piles and columns has also had a long and successful track record in both Australia and the New Zealand. One of the early galvanic encasement projects was in 2011 on the Queen St Bridge over Laverton Creek in Victoria (1).

The condition assessment undertaken on Queen Steet Bridge revealed that the severe deterioration of the pier walls was due to the low quality of the concrete and chloride induced corrosion. Chloride sampling from concrete cores showed that chlorides had reached .025% by weight of concrete which puts the structure in the extreme corrosion risk category.

Figure 4: Diagram of repair system with reinforced jacket and encased galvanic anodes

Figure 5: Galvanic anodes installed to the pier with new layer of reinforcement for structural upgrade.

The monitoring conclusions from this site in 2014, 3 years after installation, was that the combined system of the concrete and galvanic anodes is performing very satisfactorily with the embedded anodes only required to make a small contribution at this stage. From this monitoring data it is expected that the system will provide a service life of 30 years.

There are numerous other project case studies that have utilised this same galvanic encasement system over the past 14 years on structures in Australia such as Transport for NSW (which has several installations), Gold Coast City Council and QLD & WA Main Roads Departments as well as VIC Roads.

One such recent example is a project on the Gold Coast that had distributed anodes placed in FRP jacket for 28 piles. The design for this system was for 30 years of protection. (Figure 6)

Figure 6: Site photograph and close up photo of distributed anodes prior to the installation of the jacket and grout backfill material on a bridge on Gold Coast for

CONCLUSIONS

Alkali-activated distributed anodes have been used on reinforced concrete bridges throughout North America for almost 20 years and in Australia for almost 15 years. The anodes have been used in a variety of environments ranging from northern states of the US and Canada with corrosive de-icing salts to marine exposure in southern states with tropical marine climates. They have also been used successfully in nearly all states in Australia which have varied climatic exposure conditions.

Long term monitoring has demonstrated that the anode systems can be designed to satisfy NACE and AS2832.5 cathodic protection criteria while providing low maintenance cathodic protection for up to 35 years. Galvanic cathodic protection systems can provide a sustainable, low maintenance and cost-effective option for asset owners to extend the service life of corroding reinforced concrete structures compared to replacement.

ACKNOWLEDGMENTS

The authors would like to acknowledge the various bridge owners that have supported the installation and monitoring of distributed galvanic anodes by providing continued access to the structures over time including the Ontario Ministry of Transportation, the Florida DOT & VIC Roads. Any opinions, findings, or conclusions in this research are those of the authors and do not necessarily reflect the views of others.

References

- Fred Andrews-Phedonas, VIC Roads, Queen Street Bridge over Laverton Creek condition assessment and rehabilitation using encased sacrificial anodes and monitoring of performance, 9th Austroads Bridge Conference Sydney, 2014 10

AUTHOR DETAILS

| Dickinson, Andrew is the corresponding author of this paper. He is the Business Development Manager for Vector Corrosion Technologies managing the Oceania Region. Andrew is responsible for the overall management of the Oceania region.

|

| Whitmore, David is the corresponding co-author of this paper. He is President and Chief Innovation Officer at Vector Corrosion Technologies, a position he has held since 2009. He is responsible for overall management and development for the company.

|