Advances in corrosion prevention in the oil and gas industry

In the last decade, research and development has delivered vast advances in the technologies of materials selection, protective coatings, and corrosion inhibitors.

19th October 2023

Oil & Gas Technical Group – Open MIC Series (Part #1)

9th October 2023

Oil & Gas Technical Group – Latest Insights into Microbial Influenced Corrosion (MIC) Monitoring Techniques

There are many different techniques available for the detection, quantification and identification of microorganisms and the aim of this review is to discuss some examples which can be used within the oil and gas industry readily.

26th March 2023

‘Oil & Gas’ Group hosts event for over 100 in 17 countries

Over 100 registrants from 17 countries participated in our first Technical Group event of 2023, a webinar about “Latest Insights into Microbial Influenced Corrosion (MIC) Monitoring Techniques” held on the 14th February...

21st February 2023

Corrosion Under Insulation – Research and Innovation

his webinar features two fantastic guest speakers, Dr Thunyaluk (Kod) Pojtanabuntoeng, discussing some of the Recent Developments in CUI Research from Curtin Corrosion Centre and joining us from the UK, Dr Prafull Sharma, Chief Technology Officer of CorrosionRADAR spoke about Corrosion Under Insulation Risk Analytics with Monitoring Systems using Electro-Magnetic Guided Radar (EMGR). Earlier this year (2021), CorrosionRADAR won the Materials Performance (MP) / Association for Materials Protection and Performance (formerly NACE) Corrosion Innovation of the Year Award for its ground-breaking Predictive Corrosion Under Insulation (CUI) Monitoring System – a next generation technology solution that is transforming the global response to the enormous industrial challenges created by CUI.

15th November 2021

Third Generation Polysiloxane Technology

The ACA's Oil and Gas Technical Group was thrilled to Host Peter Bock for a presentation on Third Generation Polysiloxane Technology. Third Generation Polysiloxane (TGPS) ambient curing CUI mitigation coatings have been used in the petrochemical and processing industries for over five years since the “third generation” concept was introduced at NACE Corrosion 2017. These coating technologies have demonstrated positive results in both shop and field application for asset management in elevated temperature, cryogenic and cyclic applications across -196 to 650o C/ (-321 to 1200o F) operational temperatures. TGPS coatings have also demonstrated effective use of a two-step (primer-insulation) CUI mitigation coating approach operating up to 400o C/750o F, when compared to the traditional (CUI coating-fibrous insulation-cladding) systems.

5th September 2021

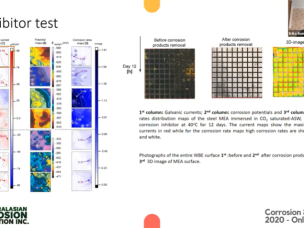

Application Of Multi-Electrode Arrays To Improve The Understanding Of Corrosion Caused By Microbes And Deposits

Presenter E.M. Suarez is a Ph.D. candidate at Curtin Corrosion Centre (CCC), Curtin University. She is a Microbiologist with experience in Microbiologically Influenced Corrosion (MIC), Under-deposit Corrosion (UDC), corrosion inhibition, environmental biotechnology, oil and gas biotechnology and microbiology associated with bioremediation processes.

2nd August 2021

Stress Corrosion Cracking (SCC) Is A Threat To Pipeline Integrity Management?

With the growing gas industry, gas pipelines have been developed rapidly in terms of safety, economy, efficient and on time delivery. Most of the gas pipeline have seen their design...

29th July 2021

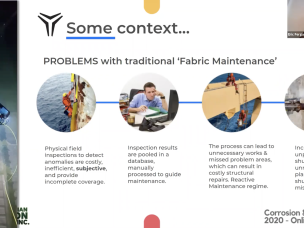

Automatic Detection and Classification of Corrosion with Convolutional Neural Networks

Continuous Fabric Maintenance (FM) is crucial for uninterrupted operations on off-shore oil and gas platforms. A primary FM goal is managing corrosion onset across the platform surface. Currently, physical field...

21st July 2021

Microbially-Induced Corrosion (MIC) in the Oil and Gas Sector

The ACA's Oil and Gas Technical Group hosted International guest Speaker Torben Lund Skohus and local experts Margarita Vargas and Laura Machuca for an interactive Forum focused on experiences with Microbially-Induced Corrosion (MIC) in the Oil and Gas Sector.

10th December 2020

Detection and Prevention of Corrosion in the Oil & Gas Industries

The Oil & Gas Technical Group provides a technical platform for the Oil & Gas Industries. The forum to discussed the latest developments and best practice in materials engineering, corrosion...

11th September 2018

Detection and Prevention of Corrosion in the Oil & Gas Industries

The Oil & Gas Technical Group provides a technical platform for the Oil & Gas Industries. It is a forum to discuss the latest developments and best practices in materials engineering and corrosion control in onshore and offshore environments.

26th August 2018

Moisture as a cause of CUI

Moisture as a cause of CUI Andy Hoffman Moisture is one of the major factors to consider when investigating corrosion under insulation (CUI). Accumulating water within an insulation system can...

11th September 2017